RFID Oil Drill Pipe Tag (RFID oil drill pipe tag) is a dedicated RFID tag for oil drill pipe tracking and management. The following is a detailed introduction to the RFID Oil Drill Pipe Tag:

Product characteristics

Resistance: The RFID Oil Drill Pipe Tag has excellent resistance to the erosion of drilling fluids, hydraulic press fluids (including hydrogen sulfide) and other substances.

High temperature and high pressure test: Verified by high temperature and high pressure stress tolerance test to ensure stable performance in extreme environments.

Vibration and chemical resistance: Survival and performance tests under extreme pressure, vibration, temperature and chemical conditions ensure reliability in practical applications.

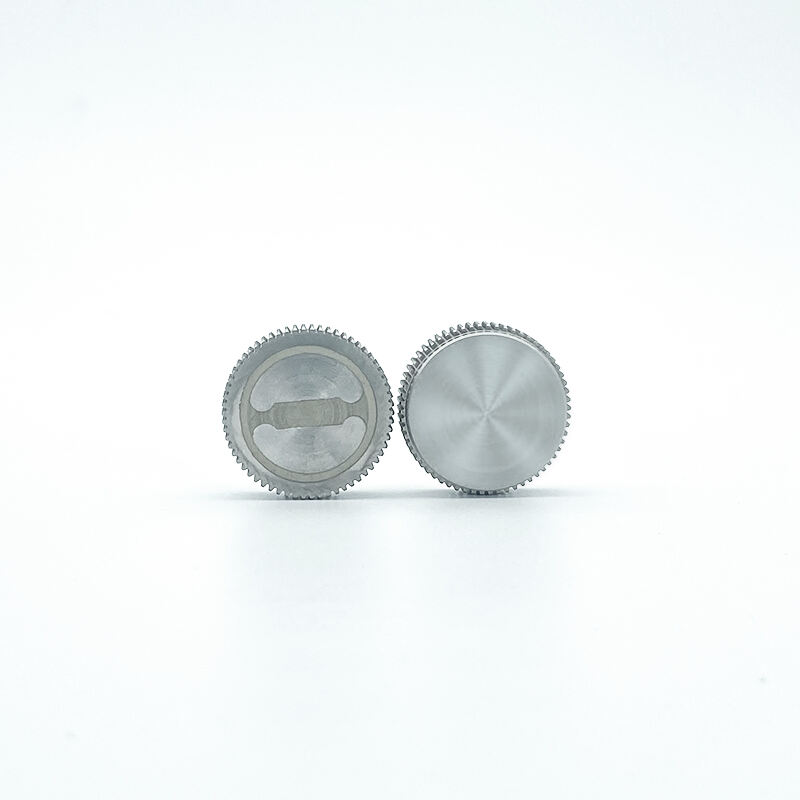

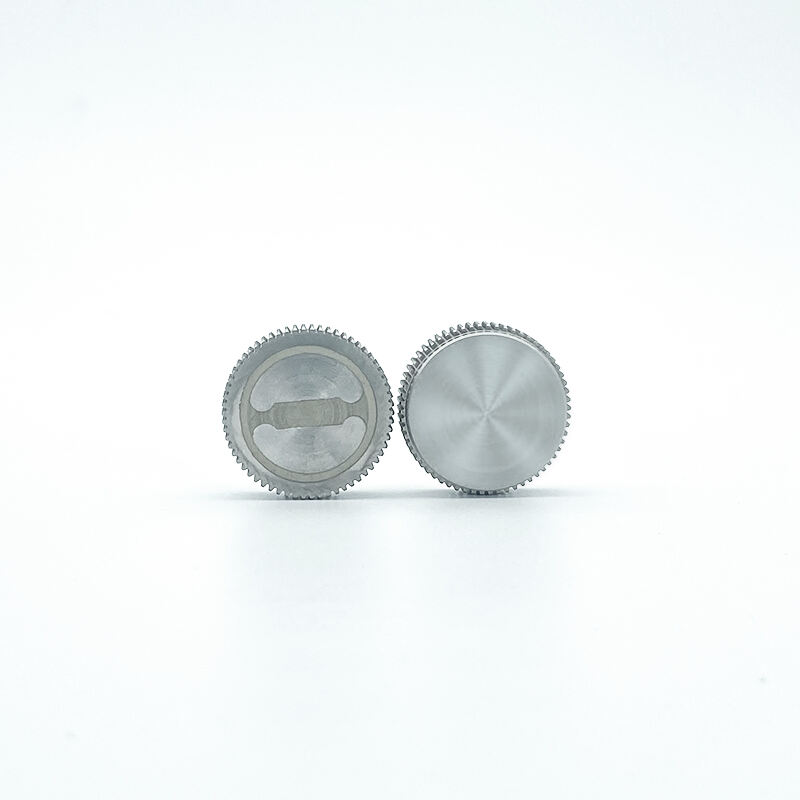

Design safety: The design is designed to be quickly embedded into the surface of the object to be managed, while ensuring that it is safe and reliable and does not loosen during downhole operation.

Application value

Asset management: Oil Drill Pipe is an important asset of oil mining enterprises, RFID Oil Drill Pipe Tag can help enterprises achieve scientific and effective asset management, reduce the risk of early scrap of drill pipe or insufficient inventory of drill pipe.

Prevention of drill pipe leakage: By recording drill pipe working hours and combining with big data algorithms, the average working hours of drill pipe leakage can be predicted, so that measures can be taken in advance for maintenance or replacement to avoid production accidents.

Improve management efficiency: Compared with the traditional manual recording and summary statistics, RFID Oil Drill Pipe Tag can achieve automated, real-time data recording and reporting, greatly improving management efficiency.