|

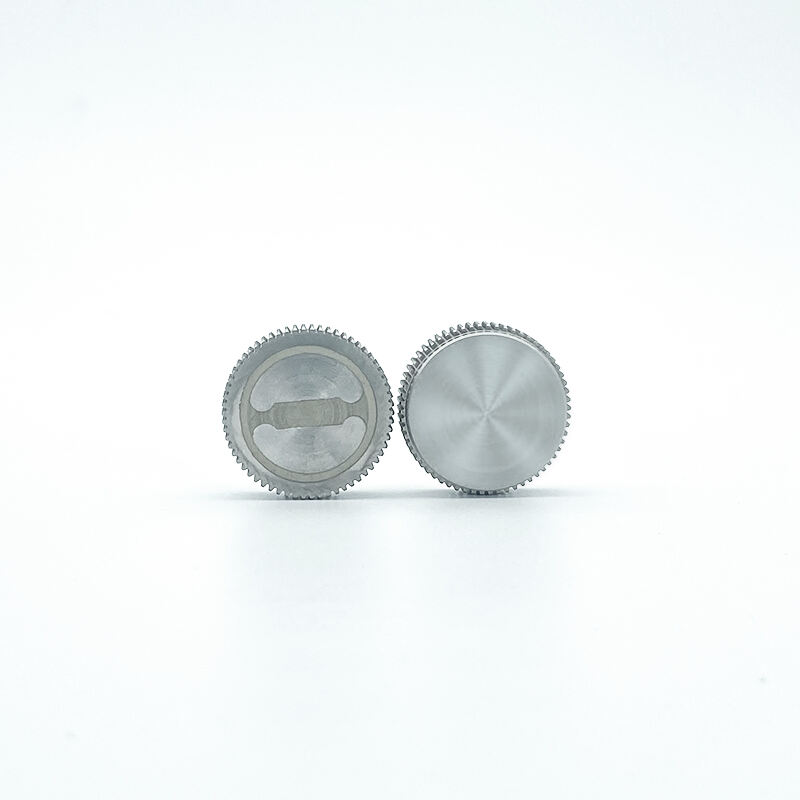

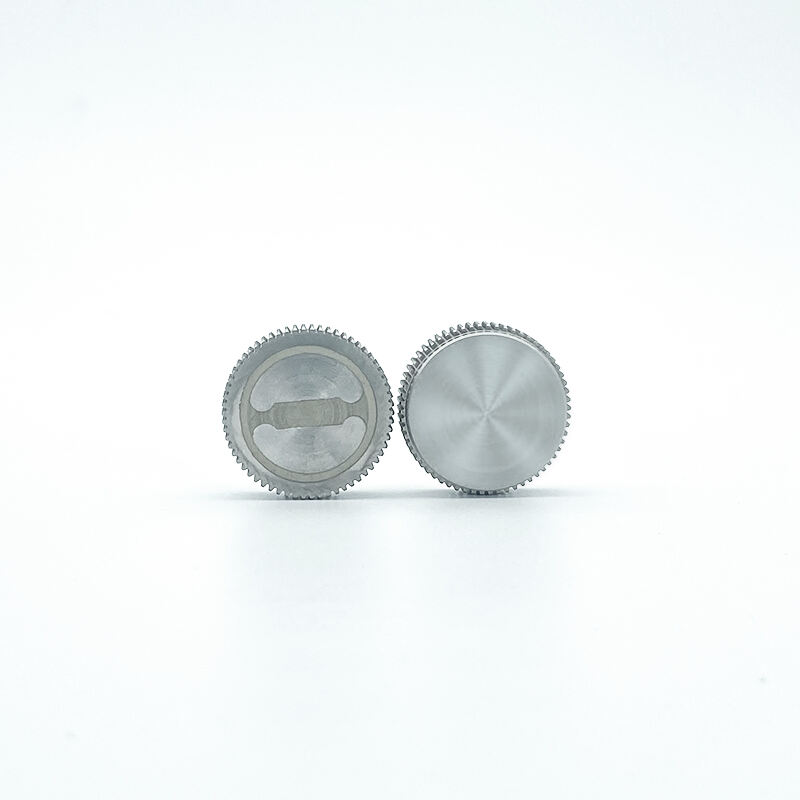

Product name |

RFID oil drill pipe tag |

|

Chip |

Alien Higgs3 |

|

Dimensions |

25mm |

|

Material |

Stainless steel + engineering plastics PEEK |

|

IP Rating |

IP 67 |

|

Application Temp |

-40-300℃ |

|

Operating Temp |

-40~70℃ |

|

Memory |

EPC 96bits, USER 512bits |

|

Frequency range with the best performance |

902-928MHz |

|

IC Life |

Write endurance of 100,000 cycles Date retention of 50 years |

|

Protocol |

ISO/IEC 18000-6C |

Detailed description:

A drill pipe is one of the most important assets of oil exploration enterprises, the service life of a drill pipe affects the normal drilling operation directly.

By implanting rfid drill pipe label, the drill pipe can record the times the drill pipe is used for maintenance, early warming and other information automatically the oil mining enterprise can strictly control the drill pipe life, via the implantation of RFID drill pipe label in practical use at the same time reduce the occurrence of drill pipe accidents and losses caused by it.

Oil drilling platforms can make every drill pipe in a good working state and improve production efficiency by using RFID drill pipe label system.

|

Product name |

RFID oil drill pipe tag |

|

Chip |

Alien Higgs3 |

|

Dimensions |

25mm |

|

Material |

Stainless steel + engineering plastics PEEK |

|

IP Rating |

IP 67 |

|

Application Temp |

-40-300℃ |

|

Operating Temp |

-40~70℃ |

|

Memory |

EPC 96bits, USER 512bits |

|

Frequency range with the best performance |

902-928MHz |

|

IC Life |

Write endurance of 100,000 cycles Date retention of 50 years |

|

Protocol |

ISO/IEC 18000-6C |